Количката ви в момента е празна!

Introducing Prusa CORE One: The new fully enclosed CoreXY 3D printer with active chamber temperature control!

We are excited to introduce the new Prusa CORE One!

By Jo Prusa

Detailed description and lots of unboxing stuff, so let’s dive right in!

Video:

https://www.youtube.com/watch?v=O04RM-KCP68&t=1s

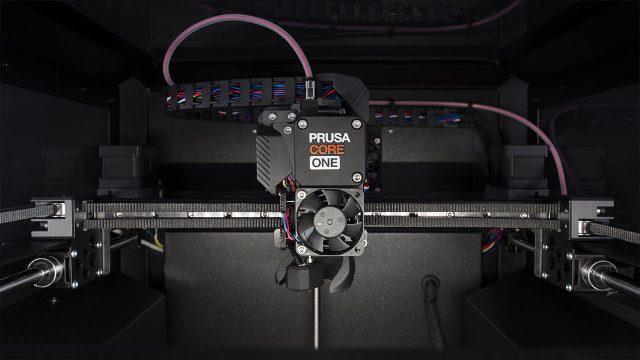

CORE One is a fully enclosed CoreXY 3D printer with active temperature control. It is a machine focused on quality and speed, and it is extremely robust. You can find the full list of technical specifications on the product page, but let us first provide you with some detailed information.

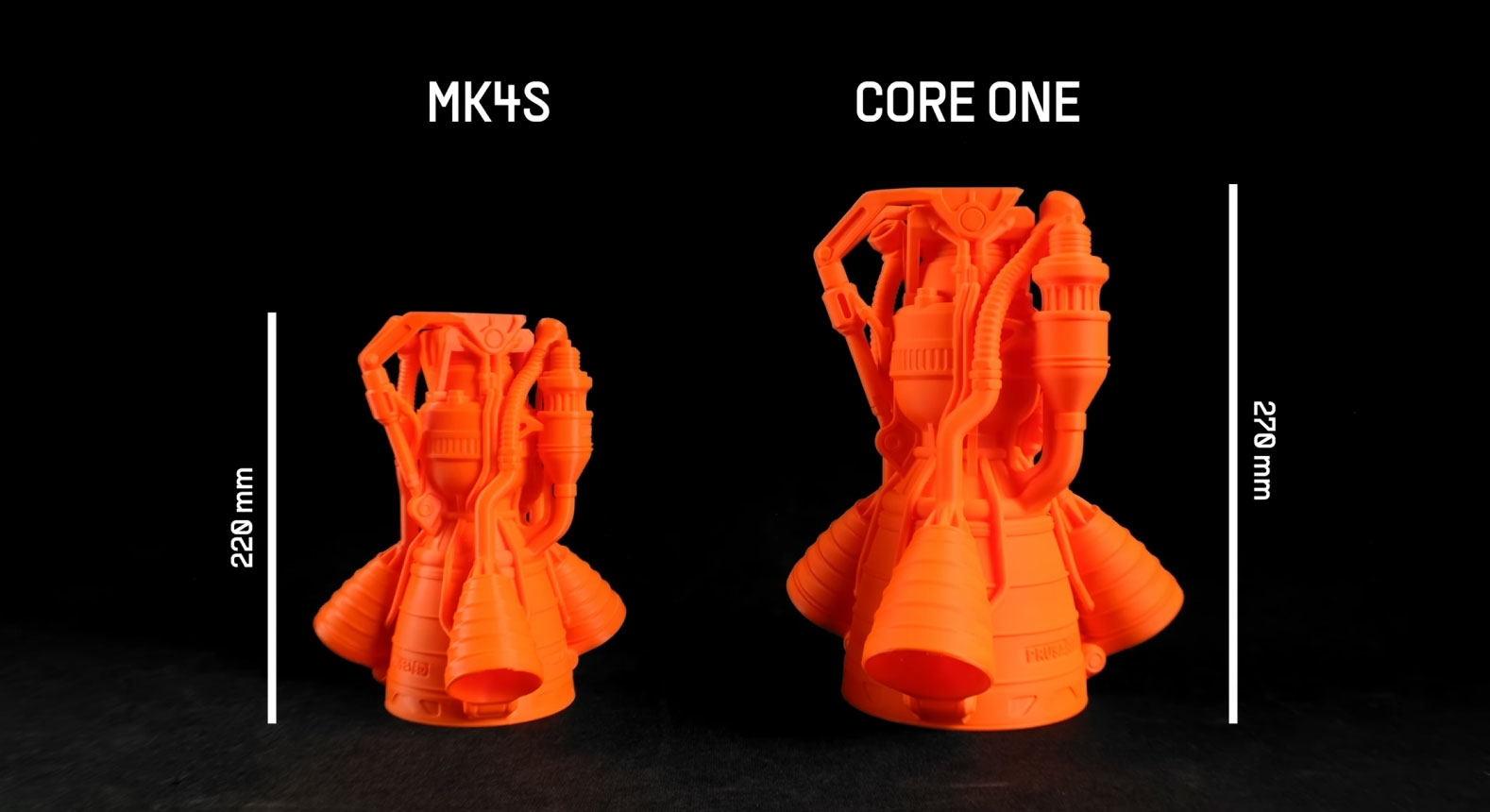

With CORE One, you won’t need one printer for quick prototypes, another for demanding materials, and yet another for high dimensional accuracy—it’s a universal „all-in-one“ machine. It is compact in size but has a large print volume (250×220×270 mm) and offers a number of intelligent design solutions, such as an exoskeletal design for maximum strength and stability. One of the remarkable things is that it allows you to print PLA and PETG with the doors closed – which is not as common as you might think. We have invested all our knowledge from the development of the XL, AFS, and even the HT90 into it.

The important thing here is that CORE One is designed to coexist with MK4S, it is not intended to be its successor, and we will continue to manufacture and support MK4S with firmware updates and even additional accessories, such as a USB-C camera for monitoring printing. If you mainly print with PLA and PETG, an open-frame printer is an excellent choice. CORE One is the first in a new product line, hence the different name.

The development of CORE One is now complete, and we are finishing the final stages of testing, with full production starting in January 2025. We are already using CORE One printers in our internal print farm.

A fully enclosed 3D printer – with an unusual twist!

We know CoreXY machines inside out – after all, we have the Original Prusa XL and Prusa Pro AFS. Although CoreXY is perceived by many as „the next step in 3D printing,“ this is not necessarily true – there are some drawbacks. The MK4S still offers exceptional print quality, high speeds, and easy access to all components. And speaking of AFS: we couldn’t just take the printer from it and turn it into a mass-produced machine because it wasn’t designed to be individually enclosed.

However, we invested a lot in researching heated chambers and cooling with the Prusa Pro HT90, and we wanted these technologies to be implemented in other products as well. A closed CoreXY 3D printer is nothing new these days, so we had to make sure we were bringing something new and useful to the table.

We focused on three main areas when engineering the new machine:

- Clever exoskeleton design with high-quality materials

- Super-compact chamber capable of reaching 55 °C with active temperature control so it can print anything from PLA with the door closed to PA11 Nylon in top quality

- A new platform for the future, that’s not a welded or glued box which is impossible to repair

I guess I don’t need to mention that we wanted to keep our signature qualities – like outstanding print quality, long-term reliability, premium materials, low maintenance, and the “made to last” approach. Those are the things you probably expect from us by default.

The new design is based on an exoskeleton structure, often seen in nature (crustaceans, insects), where the outside skin serves as structural support for the body. In our case, it leads to both improved printer robustness and great efficiency of manufacturing: the same parts serve as the printer frame and also provide the final design. So unlike other printers, this isn’t a welded cube with an enclosure around it or an open-frame printer in a box.

Thanks to the space-efficient body with recesses on both sides, the super-compact chamber can warm up faster and reach up to 55 °C. This is perfect for advanced materials (ASA, ABS, PC, Nylon) which require stable, elevated temperatures. But we wanted to take the heated chamber one step further.

The back of the printer hosts dual fans for active chamber temperature control. When you print with PLA or PETG, the fans ensure the temperature inside is as low as possible for maximum print quality.

And this is really important: about 90 percent of all prints are made with PLA or PETG. These materials perform rather poorly in elevated temperatures. This is why it’s a common practice for manufacturers (yes, even us – check the MK4S Enclosure instructions!) to ask you to remove the top enclosure panel and/or keep the printer’s door open. And honestly, the door panel then sticks out like a sore thumb, and many users are not even aware they should do this. To put it simply: Keeping the doors open goes completely against the idea and benefits of an enclosed printer.

However, the Prusa CORE One prints PLA and PETG beautifully even with the door closed, all nice and tidy. The only thing you need to do is to open a tiny vent on top of the printer, so the fans can draw colder air from the room.

And one more thing regarding the door (as well as all other transparent panels). They are made from a high-end polymer, so they are virtually indestructible – perfect for any kind of workplace and also super safe for transport. We didn’t want to use glass because it’s simply way too fragile.

We made the body of the printer as compact as possible and implemented various smart design choices. For instance, the spool is not in a hard-to-reach space (i.e., on the back). Instead, it sits nicely on the side in a recess, so it’s perfectly flush with the side of the printer, keeping a small footprint. The other recess can be easily used for all sorts of holders, organizers, and other things you design. The overall space (w×d×h) you need for the CORE One is 30% smaller compared to the MK4S and a whole 50% smaller compared to the MK4S in the Enclosure while offering a 30% increase in print volume!

Focused on Outstanding Print Quality

The CORE One is equipped with our Nextruder – and all 3D printers that used it so far received top scores in print quality benchmarks. It features the upgraded 360° cooling from the MK4S for outstanding print quality and great overhang performance – this means you can use fewer supports with your prints (or no supports at all), saving both material and print time.

The Nextruder has all the proven features for effortless, high-quality printing – this includes the extremely precise Loadcell sensor for an always-perfect first layer. The Loadcell sensor does not rely on visual data. It cannot be thrown off by reflective or textured surfaces, doesn’t need to be recalibrated every time you swap the nozzle or hotend, and it’s so good it can pretty much create a beautiful first layer even on a piece of wood. You also get easy access to quick-swap hotends, a high-flow nozzle as a standard and more.

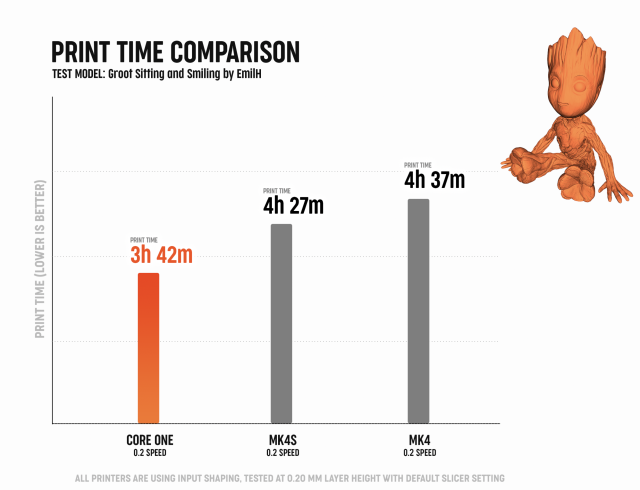

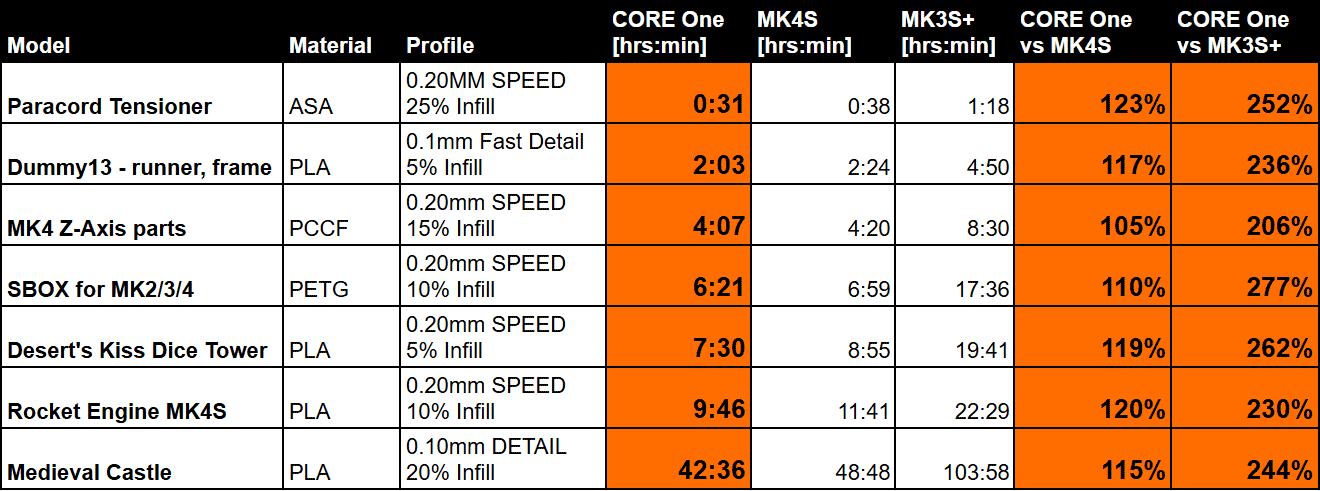

And while the MK4S was already pretty damn fast, and it could beat some of the fastest printers on the market, the CORE One goes further, reducing the print time by another 15-20% depending on the type of the project. However, there’s a massive advantage: you don’t have to limit your projects by a narrow selection of special “high-speed” filaments. The CORE One is simply fast with any filament on the market, you won’t find any fine print or asterisks next to our numbers. It’s high speed without a catch.

The CORE One performs incredibly well with a huge range of materials thanks to the chamber that heats up to 55 °C. From PLA and PETG to ASA, ABS, and PC, all the way to demanding materials like Polyamides (Nylon). This way, the CORE One covers pretty much every field: from effortless and hassle-free printing at home to the production of fast prototypes, durable functional parts, and even final products ready to be sent to customers.

CoreXY – Prusa Style

We have always designed our machines as 3D printing workhorses, because we rely on them in our manufacturing, too. We run a 3D print farm with over 600 printers and the compact design of the CORE One will allow us to fit even more machines in the same space. And we have done more things to make the CORE One the ultimate print farm machine: compact footprint is one thing, but there’s more. Thanks to the fans in the back, you can connect the printer to the air extraction system, the door opens to 180° so they don’t stick out and won’t block a more narrow space/corridor. You can even flip the hinges and the door to the other side. And the entire machine was made with low maintenance and a long lifespan in mind.