Your cart is currently empty!

12 of the best 3D printed implants.

In recent months, 3D printing has experienced a real boom in applications in the medical sector. We recently presented you a selection of the most innovative 3D printed orthoses in the sector.

The ability to add various functionalities to 3D printers now allows customization of available devices, based on the specific needs and desires of each patient, at lower material costs and shortened printing time.

3D printing is a relatively new technology that can be used to design and create various medical devices.

Today we will look at 3D printed implants – organ replacements, to treat disease or supplement motor function for a long period of time.

As many know, most implants today are made of biocompatible titanium.

In most cases, the human body accepts the material very well – a key point when talking about placing implants.

The first 3D printed clavicle implant with PEEK

Kunming University Hospital and 3D thermoplastic printer manufacturer IEMAI 3D have developed the first 3D printed clavicle implant using PEEK material.

Why PEEK?

The patient in question could not have metal implants because he had to undergo chemotherapy sessions.

The doctors decided to use FDM 3D printing technology and print the implant with one of the most durable plastic materials currently available – PEEK. After the successful implantation, it was found that the patient’s body accepted the implant without any complications. Titanium sternum implant

A patient with a specific bone disease was saved with the help of 3D printing.

A patient from Melbourne, Australia, has had parts of his breastbone and surrounding tissue removed as a result of his illness. This type of surgery is almost like an amputation, as the removed bones must be replaced with patient-specific implants.

Dr. Michelle Harden from the Royal North Shore Hospital in Melbourne sought assistance from 3D specialists from Anatomics to fabricate and print the specific sternum bones. Mandible implant for a child in China

For the first time, a 3D printed implant was placed on a child’s lower jaw in China.

The child had a rare tumor of the mandible, and its removal required the excision of a large part of the lower jaw, as a result of which the child ended up with a significant facial malformation.

Doctors replaced the missing part of the child’s lower jaw with a 3D printed titanium alloy implant based on digital models of the jaw for a perfectly designed and adapted personalized implant.3D printed eardrums successfully implanted

In South Africa, a medical team led by Prof. Mashudu Tsifularo successfully implanted 3D printed titanium eardrums. The patient lost his hearing as a result of a car accident, but after the successful surgery, he fully restored his hearing thanks to 3D printed titanium implants placed in his middle ear. Titanium spinal implant

Amit Bhanot suffers from ankylosing spondylitis, a serious arthritis that causes inflammation of the spine. He was diagnosed with the disease in the 1990s and has lost much of his mobility over the years.

In 2017, he visited the All India Institute of Medical Sciences (AIIMS) in India, where Prof. Rajesh Malhotra, head of orthopedics, diagnosed the need to create an implant for the patient.

Initially, several 3D models of vertebral implants were created, printed using FDM technology. The implants were then processed and printed from titanium using EOS technology. 3D printed jaw implant after tumor removal

Anelia Mayber is an Australian patient who received a 3D printed mandibular implant that allowed her to reconstruct her face. The patient suffered from a malignant tumor in her jaw and teeth, which doctors had to remove immediately, but as a result, she lost part of her face, resulting in significant facial deformity. After more than 5 hours of surgery, the result for Anelia Mayber is more than successful. Renishaw’s ribs from Wales

A Welsh patient lost three ribs and part of his rib cage due to a chest tumor. The tennis ball-sized tumor was successfully removed after an 8-hour operation, with the missing bones replaced with custom 3D printed titanium alloy implants. The first 3D printed rib implant with flexible polyamide

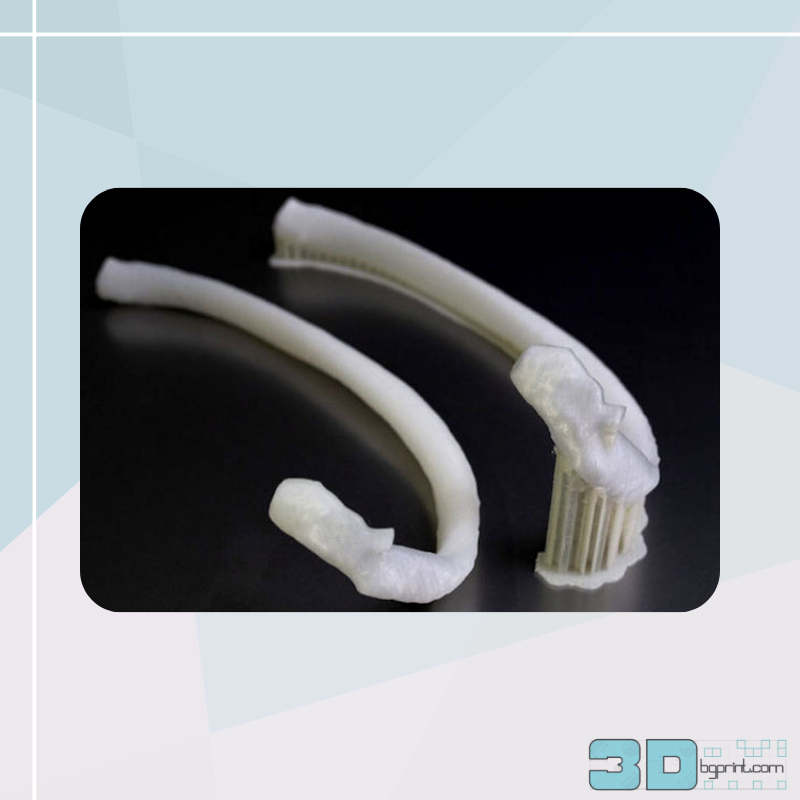

In Bulgaria, patient Ivaylo Yosifov arrived at Tokuda Hospital with a diagnosis of tonsillitis and left with a new 3D printed rib.

Doctors discovered a malformation in Ivaylo’s ribs that was pressing on his lungs, which led to immediate surgery. The most appropriate solution was to fabricate and 3D print a new rib, made by 3Dbgprint.

“3Dbgprint” creates and prints the world’s first flexible polyamide implant, saving Ivaylo’s life.

Here you have the opportunity to learn in detail about the printing of the implant by 3Dbgprint.

FDA implants

“Medicrea” is a company based in Lyon, specializing in implant design.

Among their production processes we also find 3D printing.

In 2014, Medicrea was the first French company to launch a 3D-printed spinal implant made of PEEK, a thermoplastic known for its high strength and durability. Since then, Medicrea has been developing a wide range of 3D-printed titanium implants. Cranial implant

Tiffany Cullen, 20, underwent surgery for a massive brain tumor. After a 6-hour operation that involved drilling into her skull, surgeons were able to remove the tumor, but a few days later, the patient developed complications. Doctors removed parts of her skull to relieve the abnormal pressure. For 3 months, Tiffany lived with a skull 5 inches smaller until doctors created a 3D-printed implant made of titanium, plastic, and calcium. One of the oldest “solutions” on the market…

In 2018, we celebrate the anniversary of the first titanium 3D printed hip implant: 10 years after the surgery, the implant is still in good condition and the patient feels excellent with fully restored motor functions.

While a traditional hip implant must be replaced every 10 to 15 years, the 3D printed implant appears to be more durable, resulting in fewer complications for the wearer. 3D Printed Implant for a Dog

Who said 3D technology is only for humans?

The example of a Siberian Husky speaks for itself: the dog received a 3D printed titanium implant that replaced the top part of its skull that had to be removed during critical surgery.

One of the advantages of 3D printing is that it offers complete customization of the implant: it is perfectly adapted to the dog’s morphology. It is then more easily integrated into the skull, allowing the bone to grow into the implant extremely quickly.Source: https://www.3dnatives.com/en/best-3d-printed-implants-230720195/?fbclid=IwAR0PdIteL5V_o7joXFKFKIpgCbCK6KFWJwNT3hGbMXZgm-l7Ug23R1zoKvc