Your cart is currently empty!

Thermoforming

Thermoforming is a manufacturing process in which a plastic sheet is heated to a flexible molding temperature, formed into a specific shape in a die, which is then trimmed in a specific way to create a usable product.

What is thermoforming?

A process in which a product or matrix is created by heating a film of a specialized material. The sheet or “film,” when referring to thinner gauges and certain types of materials, is heated in a furnace/oven? to a high enough temperature that it can be stretched into or over a mold and cooled to the finished shape. Its simplified version is vacuum forming.

In its simplest form, a small benchtop or laboratory machine can be used to heat small cut sections of plastic sheet and stretch it onto a mold using vacuum. Thermoforming is often used for trial and prototype parts.

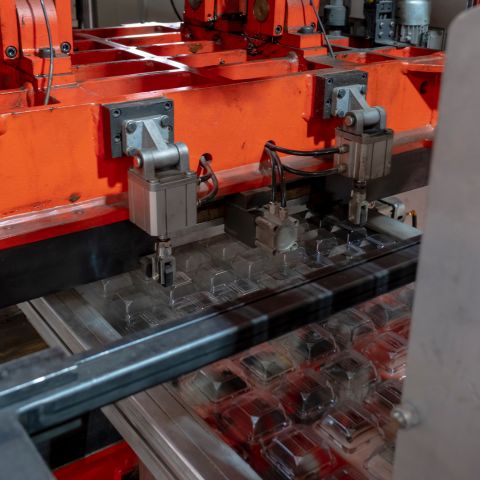

In complex, high-volume applications, very large production machines are used to heat and shape the plastic sheet and cut the formed parts from the sheet in a continuous high-speed process and can produce many thousands of finished parts per hour depending on the machine and the size of the mold and the size of the molded parts.

In its simplest form, a small benchtop or laboratory machine can be used to heat small cut sections of plastic sheet and stretch it onto a mold using vacuum. Thermoforming is often used for trial and prototype parts.

In complex, high-volume applications, very large production machines are used to heat and shape the plastic sheet and cut the formed parts from the sheet in a continuous high-speed process and can produce many thousands of finished parts per hour depending on the machine and the size of the mold and the size of the molded parts.

Thermoforming fabrication size

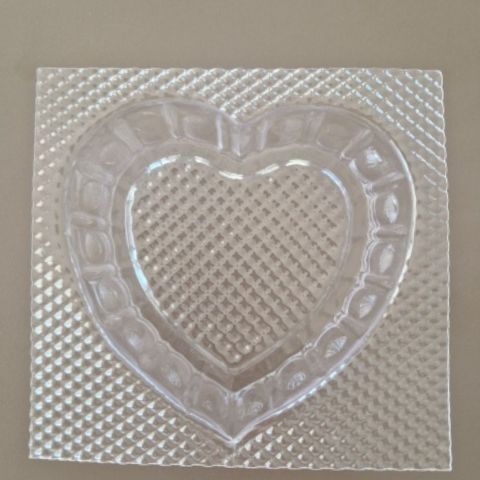

A3 format (297 x 420 mm) is a popular size for thermoformed product production. It is large enough to accommodate multiple components or products, but compact enough to produce efficiently.

Advantages of A3 format:

Flexibility: It is suitable for producing a wide range of products, including packaging, electronic components, toys, prototypes, etc.

Efficiency: A3 format is optimized for producing large quantities of products with minimal waste.

Availability: A3 format is widely available, making it an economical option for production.

Advantages of A3 format:

Flexibility: It is suitable for producing a wide range of products, including packaging, electronic components, toys, prototypes, etc.

Efficiency: A3 format is optimized for producing large quantities of products with minimal waste.

Availability: A3 format is widely available, making it an economical option for production.

Thermoforming technologies

There are many different thermoforming technologies that can be divided into two main categories: vacuum forming and injection molding.

Vacuum forming: The most common type of thermoforming. Vacuum forming uses a vacuum to press a heated plastic sheet onto a mold.

Injection molding: Injection molding uses compressed air or another gas to force a heated plastic sheet into a mold. This process can be used to create more detailed and complex shapes than vacuum forming.

Thermoforming is a flexible process that can be used to produce a wide range of products, such as food packaging, tool molds, car door panels, motorcycle helmets, and even aircraft parts.

Vacuum forming: The most common type of thermoforming. Vacuum forming uses a vacuum to press a heated plastic sheet onto a mold.

Injection molding: Injection molding uses compressed air or another gas to force a heated plastic sheet into a mold. This process can be used to create more detailed and complex shapes than vacuum forming.

Thermoforming is a flexible process that can be used to produce a wide range of products, such as food packaging, tool molds, car door panels, motorcycle helmets, and even aircraft parts.

Thermoforming materials

PET (polyethylene terephthalate) for thermoforming

This material is a commonly used food packaging material. PET is a milky white or light yellow, highly crystalline polymer, the surface is smooth and shiny.

In a wide temperature range with excellent physical and mechanical properties, long-term use temperature up to 120℃, excellent electrical insulation, even at high temperature.

Usually through the reinforcement, filling, mixing and other methods to improve its processability and physical properties, to improve the effect of glass fiber greatly improve the resin resistance, heat resistance, chemical resistance, electrical properties and snow resistance!

In a wide temperature range with excellent physical and mechanical properties, long-term use temperature up to 120℃, excellent electrical insulation, even at high temperature.

Usually through the reinforcement, filling, mixing and other methods to improve its processability and physical properties, to improve the effect of glass fiber greatly improve the resin resistance, heat resistance, chemical resistance, electrical properties and snow resistance!

You have good mechanical properties, impact strength is 3 to 5 times greater than other films, folding well.

High transparency, can block UV light, good gloss.

Non-toxic, tasteless, healthy and safe, can be used directly in food packaging.

It has excellent high and low temperature performance, long-term use in the temperature range of 120℃, short-term use can withstand 150℃ high temperature, resistant to -70℃ low temperature, as well as high and low temperature mechanical properties.

The permeability of gases and water vapor is low, both an excellent gas barrier and water, oil and odor.

EVA (Ethylene Vinyl Acetate Copolymer) for Thermoforming

EVA, a copolymer of ethylene and vinyl acetate, has a wide range of applications and is suitable for making elastomeric materials due to its flexibility and the fact that it can be processed in combination with other thermoplastic polymers.

Properties It has good qualities in terms of gloss, low temperature durability, waterproof properties and resistance to UV radiation, etc.

These products are designed for repeated contact with all types of food under different operating conditions (time, temperature).

Application areas of EVA. 1. Widely used in the fields of foam shoes, functional film for awnings, packaging molds, hot melt adhesive, wire and cable, as well as toys, etc.

High transparency, can block UV light, good gloss.

Non-toxic, tasteless, healthy and safe, can be used directly in food packaging.

It has excellent high and low temperature performance, long-term use in the temperature range of 120℃, short-term use can withstand 150℃ high temperature, resistant to -70℃ low temperature, as well as high and low temperature mechanical properties.

The permeability of gases and water vapor is low, both an excellent gas barrier and water, oil and odor.

EVA (Ethylene Vinyl Acetate Copolymer) for Thermoforming

EVA, a copolymer of ethylene and vinyl acetate, has a wide range of applications and is suitable for making elastomeric materials due to its flexibility and the fact that it can be processed in combination with other thermoplastic polymers.

Properties It has good qualities in terms of gloss, low temperature durability, waterproof properties and resistance to UV radiation, etc.

These products are designed for repeated contact with all types of food under different operating conditions (time, temperature).

Application areas of EVA. 1. Widely used in the fields of foam shoes, functional film for awnings, packaging molds, hot melt adhesive, wire and cable, as well as toys, etc.

More about us | 3DBGPRINT

The development of 3D technologies and 3D printing encouraged us to realize our idea and create 3DBGPRINT.

The trademark was created back in 2013, and we can boldly say that we were one of the first to introduce the Bulgarian market to innovative technologies in the field.

The company’s main goal is to introduce the Bulgarian market to innovative technologies in the field of 3D technologies.

“3DBGPRINT” is an official representative of leading manufacturers of 3D printers and materials. We have our own training base in 3D technologies and our own 3DLAB for the production of parts using various technologies (FDM, SLS, LCD, PolyJet)

The trademark was created back in 2013, and we can boldly say that we were one of the first to introduce the Bulgarian market to innovative technologies in the field.

The company’s main goal is to introduce the Bulgarian market to innovative technologies in the field of 3D technologies.

“3DBGPRINT” is an official representative of leading manufacturers of 3D printers and materials. We have our own training base in 3D technologies and our own 3DLAB for the production of parts using various technologies (FDM, SLS, LCD, PolyJet)