Your cart is currently empty!

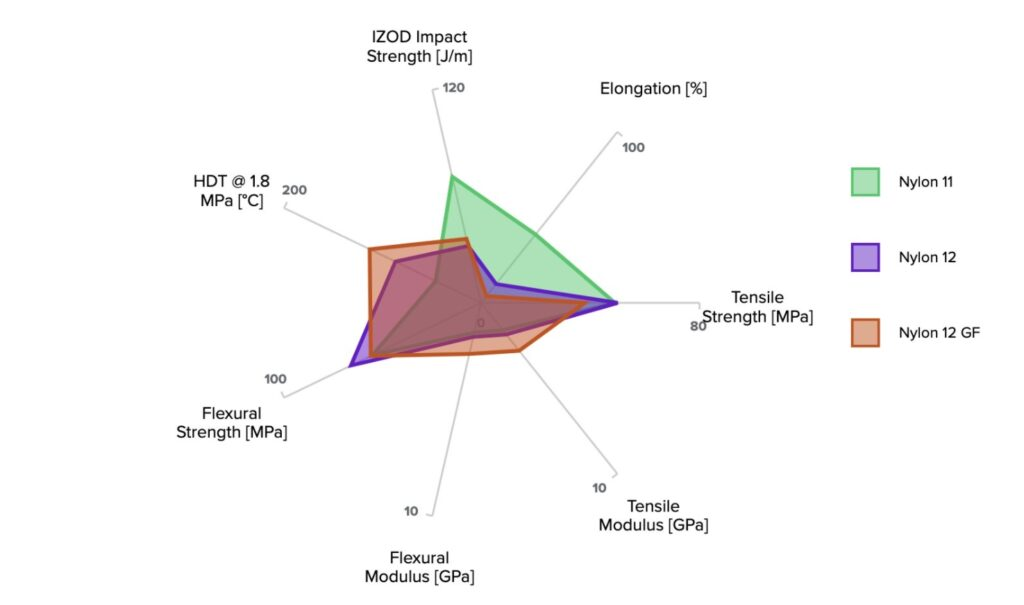

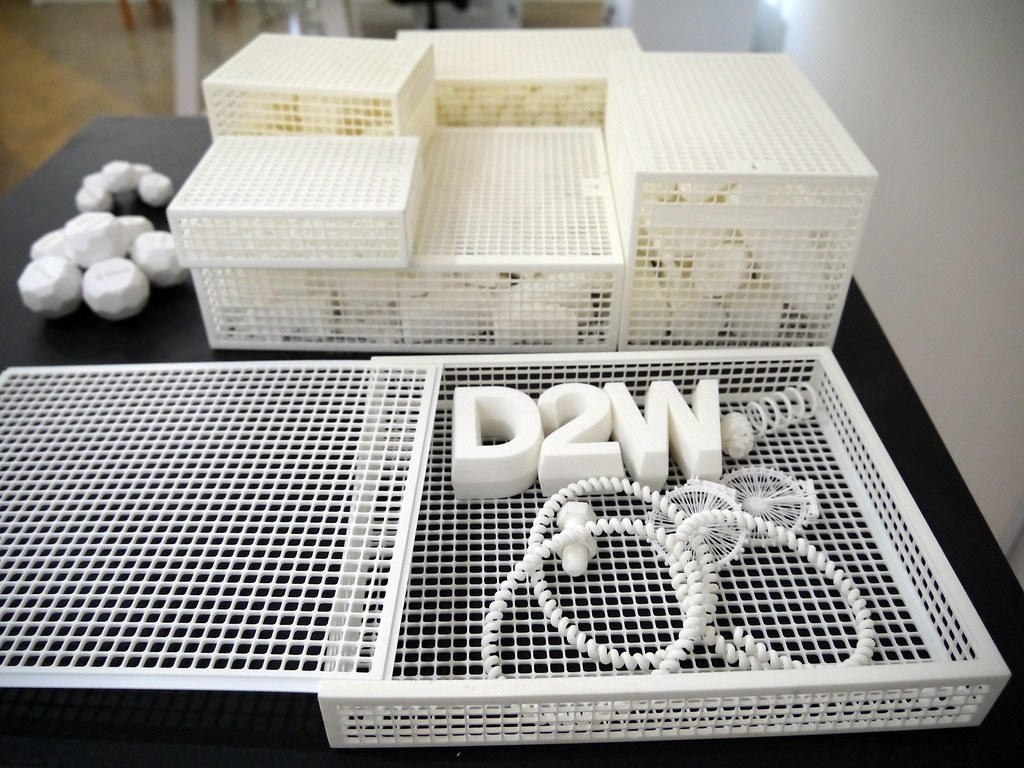

Nylon 12 is a highly capable thermoplastic for a range of functional prototypes.

Nylon 12 is a highly capable thermoplastic for a range of functional prototypes.

Nylon 12 is a highly capable thermoplastic for a range of functional prototypes.

Nylon 12 is a highly capable thermoplastic for a range of functional prototypes.

Nylon 12 is a highly capable thermoplastic for a range of functional prototypes.