Your cart is currently empty!

Description

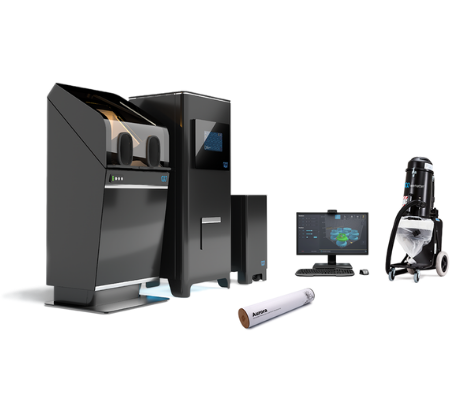

Our partner Wematter has developed and manufactured one of the easiest-to-use ecosystems for additive production of functional and durable components. Wematter’s offering consists of both hardware and software products for a complete SLS platform for easy and affordable 3D printing.

The Swedish company Wematter has the know-how for materials and the printing process to provide its customers with customized solutions for their needs. The specialized SLS printing system consists of the following products and services:

- Wematter Gravity – SLS 3D printer

- Deep Space – Cloud software

- Density – Water-jet cleaning cabinet

- Inertia – Powder collector

- Aurora – PA11, PA12 / TPU / PP – Printing powder

- Option to order a custom Wematter Gravity SLS 3D printer.

Wematter Gravity SLS 3D-printing system

Ground-breaking and easy to use SLS 3D-printing platform for additive manufacturing.

Imagine printing funtional components for testing and end-use directly at your office, with the push of a single button.

With Wematter’s novel SLS 3D-printing platform you can increase your teams performance with additive manufacturing.

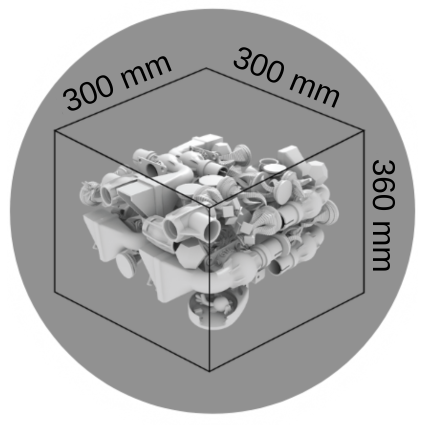

Large volume of construction

Now you can print finished products with SLS-quality without the need for dusty rooms, volume of the printing chamber / construction: over 300 x 300 x 360 mm. Wematter Gravity 3D printed components have the same strength as die casting and can replace both milled aluminum and tool investments.

SLS-Prints produced and delivered in hours

Reduce the time and cost of your SLS 3D printed parts by having your own SLS 3D printer in your office. Print functional prototypes and replacements in your own additive manufacturing system with the Wematter Gravity SLS 3D-printer

Advanced SLS technology in a user-friendly format

For the first time ever, there is an SLS system adapted for the broad masses. Wematter Gravity SLS 3D-printers are CE-marked for office use, hospital environment, lab or workshop.

This means that there are no requirements for dedicated staff, no investments in infrastructure and, above all, no complex powder handling.

Deep Space software for 3D-printing

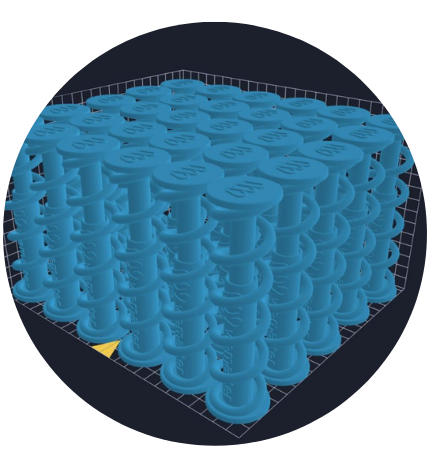

Upload your .step or .stl files directly to our web application and prepare your 3D-printing jobs from any computer.

The development of Wematter Stacker ™, software that automatically places objects in the volume of the structure and which saves time and improves productivity.

Remote monitoring of your 3D print jobs

Through an integrated camera and a constant reading of sensors in Gravity, you can follow the 3D prints everywhere, on your phone, tablet or computer.

You see the number of printed layers, a live video stream, expected end time and how many percent is done.

AURORA – POWDER MATERIAL FOR SLS 3D-PRINTERS

Technical information

Printing

- Printing technology: SLS (Selective laser sintering / powder fusion)

Volume of the printing chamber / construction: over 300 × 300 × 360 mm - Volume of a separate part: up to 300 x 300 x 170 mm, 300 x 300 x 150 mm,

- 300 х 300 х 360 mm

- Accuracy: 0.1 mm

- Double extruding

- Speed: 12 mm per hour

- Material: Aurora PA11 / PA12 / TPU / PP

- WeMote panel – 13.3 inch touchscreen with transparent camera window.

Size and weight

- Printer external dimensions: 170 x 75 x 60 cm

- Weight: 310 kg

Electrical

- Electrical: 230 V, 50-60 H

- Connecting: Ethernet 1 Gigabit

Mechanical

- Construction: steel

- Print speed: 12 mm per hour

- Stable thermal environment with Atmosphere

Software

- Cutting software: Wematter Stacker ™

- Compatible file types: .stl, .step

Wematter Gravity introduction movie