Your cart is currently empty!

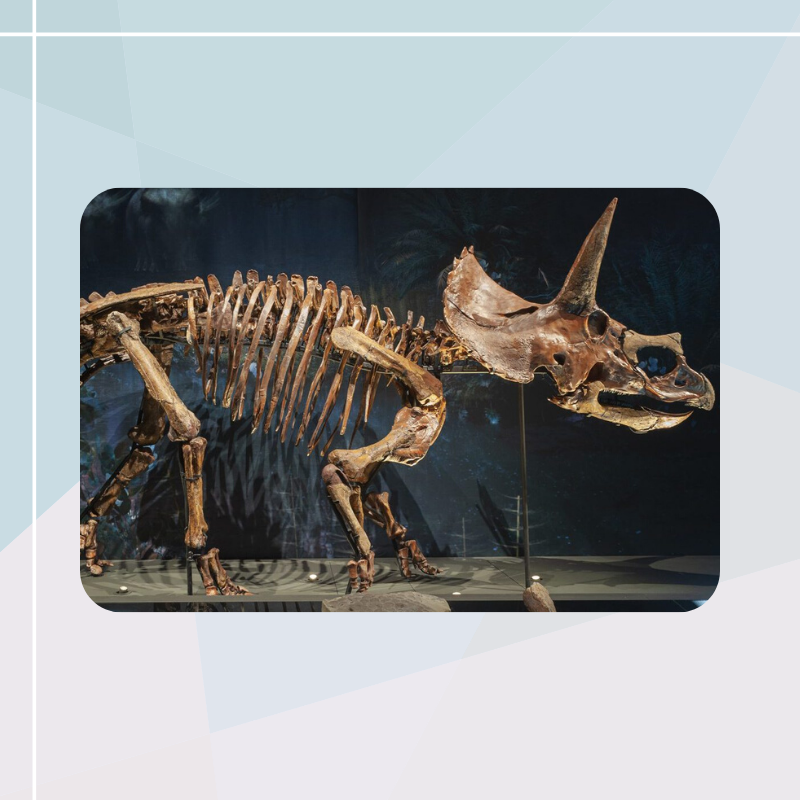

Ladies and gentlemen – Dirk Triceratops!

After months of scanning, 3D printing, mounting original bones and 3D prints, Dirk is proudly on display at the dinosaur gallery of Naturalis.

The National Biodiversity Research Center Naturalis, located in Leiden, the Netherlands, is responsible for one of the largest natural science collections in the world, numbering over 42 million species. These collections also include a 66-million-year-old Tyrannosaurus Rex skeleton, discovered in 2013 in the state of Montana, USA. And the big news is that the museum now has another dinosaur in its ranks – the Triceratops Dirk. Finally, visitors will be able to enjoy the rich collection, because after 2 years of construction work, Naturalis is opening its doors wide with a brand new museum. But let’s start with Dirk’s story, which is quite interesting. The dinosaur lived about 67 million years ago. However, its skeleton was recently discovered, excavated near Newcastle, Wyoming, USA. Although the skeleton has been found, it is not complete. It is missing bones, ribs, one of the horns, as well as a large part of the skull. At this point, Naturalis faces a real challenge – to reconstruct Dirk’s skeleton and display it in its newly opened museum. All of this is ultimately organized and only happens thanks to the modern technology of 3D scanning and large-scale 3D printing. Dr. Peter Schalch, PR and Marketing Manager at Naturalis, explains: “Modern paleontologists use 3D imaging and printing techniques as a means of reconstructing remains and skeletons during scientific excavations. In this case, a Builder Extreme 3D printer is needed, which manages to print every missing part of the dinosaur’s skeleton. This printer can actually be seen and even shows us demonstratively how things really happen in the new Naturalis museum.” The fact is that the workflow is not small before it gets to 3D printing. First, bones of other triceratops must be scanned in order to visualize Dirk’s skeleton.

“If we have a left bone, for example, and the right part is missing, we can do a mirror scan and a 3D print,” explains Schulp. “For other bones, such as the vertebrae, we had to scan a Triceratops skeleton from the collections of the Children’s Museum of Indianapolis. Its skeleton complemented what we found from Dirk. After the scan, the big 3D printing process began. This is not the first time Naturalis has used the help of 3D printing. The museum has been using this technology for several years, but until now only on a small scale:

“This technology works great if you need to 3D print smaller bones,” says paleontologist Prof. Anne Schulp, a researcher at Naturalis. “Even for a larger bone, if we combine several small ones, it will still be no problem. But if we are talking about a project like the Triceratops Dirk, we already had to seek help from a serious printer like the Builder Extreme. The bones we had to print for Dirk were between 50 and 130 cm long. That is why we invested in a Builder Extreme 1500 PRO 3D printer, which has a long print run.”

3D printed dinosaur skeleton in a museum with Builder Extreme!

In recent months, Builder Extreme has been printing 24/7 to print all of the hundreds of different elements. Many of Dirk’s bones are too fragile to be displayed at Naturalis, so they are also 3D printed and mounted on the skeleton.

For the Naturalis Museum, the details of the skeleton are of utmost importance, and therefore the 3D printing of the bones is done in the highest possible quality. Of course, some of the bones are fine, others have a complex shape, and some of them are printed with a supporting structure. Once printed, any support is removed and the bones are painted by hand. When painting, the bones are colored a slightly lighter version of the actual ones so that visitors can tell the difference.

Although Dirk is now a completed project and presented to visitors, the printer Builder Extreme 1500 PRO is already reserved for another major Naturalis project. If you want to see the printer itself, thanks to which Dirk was restored, you can also see it in Bulgaria in the showroom of 3DBGPrint – official representative of Builder for Bulgaria. You will be able to see more in the showroom of 3DBGPrint live demonstration of how it really works Builder Extreme 1500 PRO, to experience the magic of 3D принтирането and even order a free sample. Don’t hesitate – visit 3DBGPrint!Source: Builder3dprinters