Your cart is currently empty!

Introducing the Prusa CORE One: The new fully enclosed CoreXY 3D printer with active chamber temperature control!

We are excited to introduce the new Prusa CORE One!

By Joe Prusa

Detailed description and lots to unpack, so let’s dive right in!

Video:

https://www.youtube.com/watch?v=O04RM-KCP68&t=1s

CORE One is fully enclosed CoreXY 3D printer with active temperature control. This is a machine focused on quality and speed, and is extremely robust. You can find the full list of technical specifications on the product page, but let’s give you the details first.

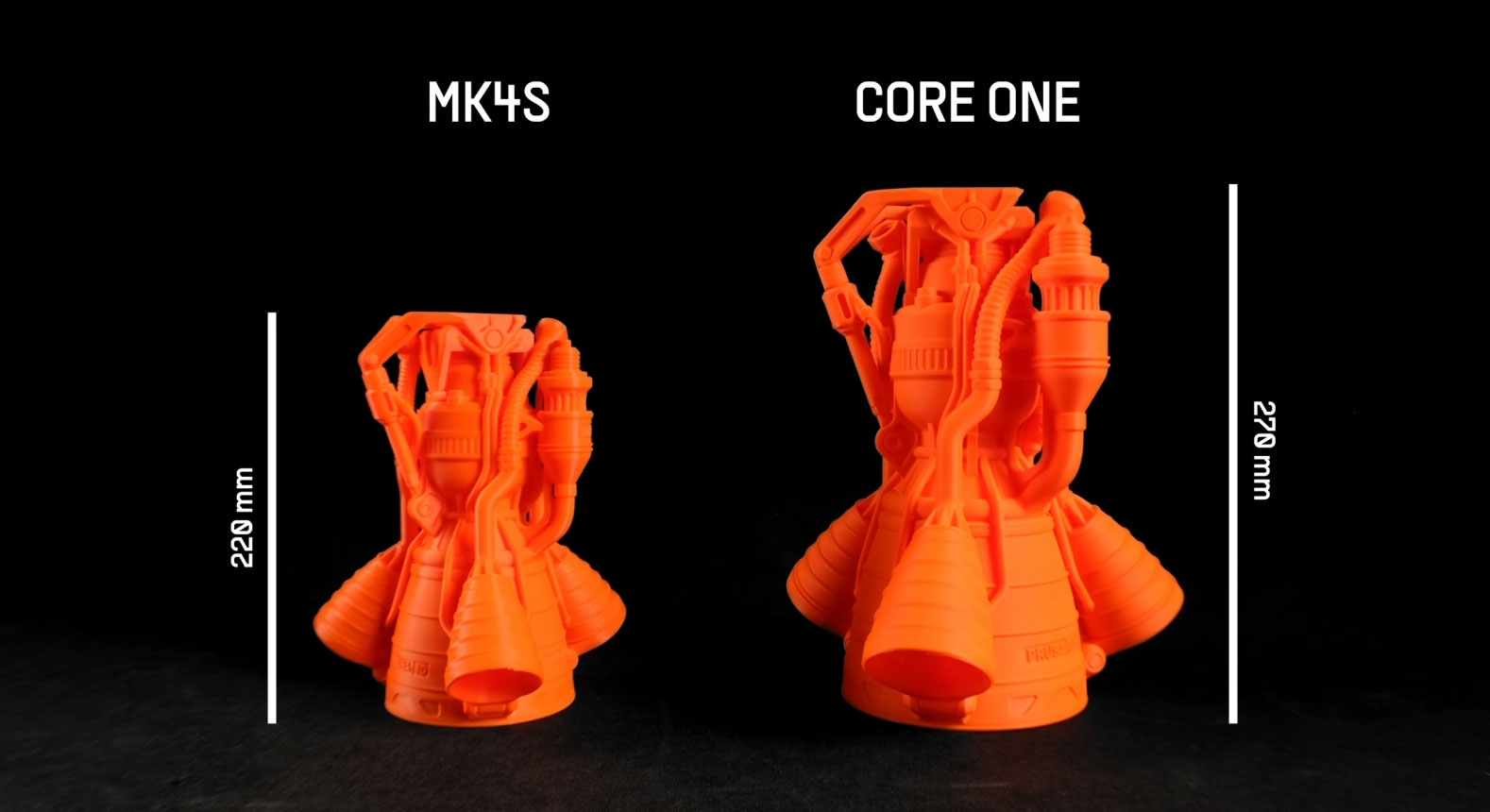

With CORE One, you won’t need one printer for quick prototypes, another for demanding materials and yet another for high dimensional accuracy – it’s a versatile all-in-one machine. It’s compact in size but large print volume (250×220×270 mm) and offers many intelligent design solutions, e.g. exoskeleton design for maximum strength and durability. One of the remarkable things is that it allows you to print PLA and PETG with closed doors – which is not as common as you might think. We put all our knowledge from developing the XL, AFS and even the HT90 into it.

The important thing here is that CORE One is designed to coexist with MK4S, not intended to be its successor and we will continue to manufacture and support MK4S with firmware updates and even additional accessories, such as a USB-C camera for print monitoring. If you print primarily with PLA and PETG, an open frame printer is an excellent choice. The CORE One is the first of a new product line, hence the different name.

CORE One development is now complete and we are finishing the final stages of testing, with full production starts in January 2025. We already use printers CORE One in our in-house print farm.

A fully enclosed 3D printer – with an unusual twist!

We know the CoreXY machines to the marrow of our bones – after all, we have the Original Prusa XL and Prusa Pro AFS. Although the CoreXY is perceived by many as “the next step in 3D printing,” that’s not necessarily true – there are some drawbacks. The MK4S still offers exceptional print quality, high speeds and easy access to all components. And speaking of AFS: we couldn’t just take the printer from there and turn it into a mass-produced machine because it wasn’t designed to be individually enclosed.

However, we put a lot into researching heated chambers and cooling with the Prusa Pro HT90 and wanted to incorporate these technologies into other products. The CoreXY closed 3D printer is nothing new nowadays, so we had to make sure we brought something new and useful.

In designing the new machine, we focused on three main areas:

- Clever exoskeleton design with high quality materials

- Super-compact chamber capable of 55°C with active temperature control so it can print everything from closed-door PLA to the highest quality PA11 Nylon

- A new platform for the future, that is not a welded or stuck box that is impossible to fix.

I guess I don’t need to mention that we wanted to keep our distinctive qualities – such as exceptional print quality, long-term reliability, premium materials, low maintenance and a “built to last” approach. These are the things you probably expect from us by default.

The new design is based on exoskeleton structure, common in nature (crustaceans, insects), where the outer skin serves as a structural support for the body. In our case, this leads to both improved printer robustness, and to great production efficiency: the same parts serve as the frame of the printer and also provide the final design. So, unlike other printers, this is not a welded cube with a housing around it or an open-frame printer in a box.

Thanks to the compact housing with recesses on both sides, the super-compact chamber can warm up faster and reach up to 55 °C. This is ideal for advanced materials (ASA, ABS, PC, nylon) that require stable, elevated temperatures. But we wanted to take the heated chamber one step further.

On the back of the printer are two fans for active temperature control in the chamber. When printing with PLA or PETG, the fans ensure that the temperature inside is as low as possible for maximum print quality.

And this is really important: about 90 percent of all prints are made with PLA or PETG. These materials perform quite poorly at elevated temperatures. That’s why it’s common practice for manufacturers (yes, even us – see the MK4S housing instructions!) to ask you to remove the top housing panel and/or keep the printer door open. And frankly, the door panel sticks out like a sore thumb and many users don’t even realize they have to do this. Simply put: Leaving the doors open completely contradicts the idea and benefits of a closed printer.

However, The Prusa CORE One prints PLA and PETG beautifully even with the door closed, everything is nice and neat. The only thing you have to do is open a small hole at the top of the printer so the fans can suck cooler air out of the room.

One more thing about the door (and all the other transparent panels). They are made of high quality polymer, so they are virtually indestructible – ideal for any kind of workplace and also super safe for transport. We didn’t want to use glass because it’s just too fragile.

We made the printer housing as compact as possible and implemented various intelligent design solutions. For example, the reel is not in a hard-to-reach location (i.e. on the back). Instead, it sits conveniently on the side in a recess so it’s perfectly flush with the side of the printer, keeping the footprint small. The other recess can easily be used for any holders, organizers, and other things you design. The total space (w×d×h) you need for CORE One is 30 % less compared to MK4S and by a whole 50% less than MK4S in the hull, while offering 30% increase in print volume!

Focus on exceptional print quality

CORE One is equipped with our Nextruder – and all the 3D printers that have used it so far, have received top marks в print quality tests . It features enhanced 360° cooling from MK4S for exceptional print quality and excellent overhang performance – this means you can use fewer supports with your prints (or no supports at all), saving both material and printing time.

Nextruder has all the proven features for seamless, high-quality printing – this includes the extremely precise Loadcell sensor for an always perfect first layer. The Loadcell sensor does not rely on visual data. It can’t be confused by reflective or textured surfaces, doesn’t need to be recalibrated every time you change the nozzle or hotend, and is so good it can create a beautiful first layer even on a piece of wood. You also get easy access to quick-change hotends, a standard high-flow nozzle, and more.

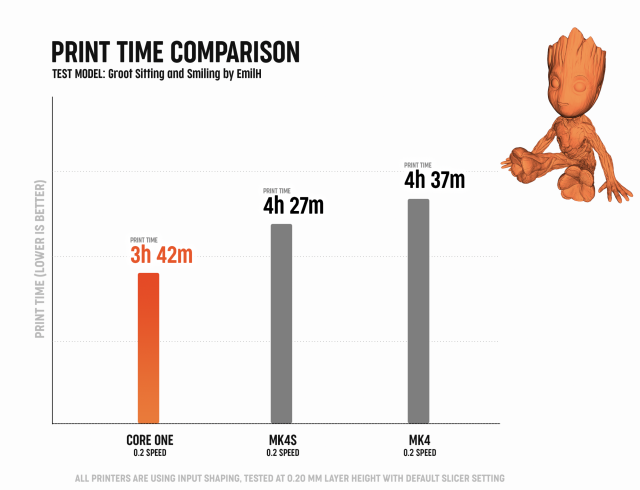

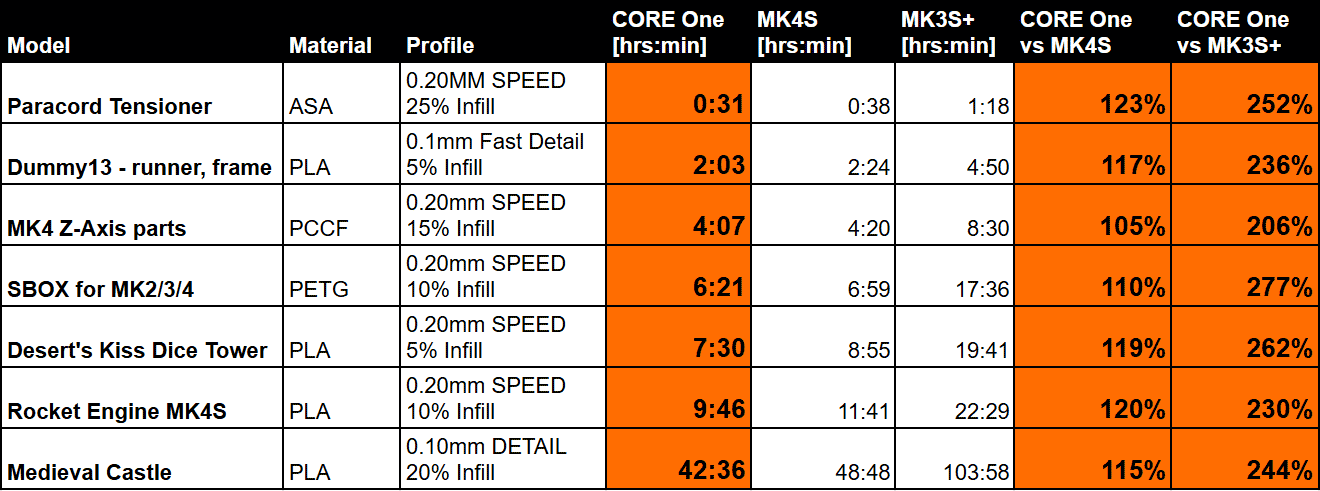

And while the MK4S was already quite fast and could beat some of the fastest printers on the market, the CORE One goes further, reducing print times by another 15-20% depending on the type of project. However, there is a huge advantage: you don’t have to limit your projects with a narrow selection of special “high speed” filaments. CORE One is simply fast with every filament on the market, you won’t find fine print or asterisks next to our numbers. It’s high-speed without any catches.

CORE One handles a huge range of materials incredibly well, thanks to the chamber that heats up to 55°C. From PLA and PETG to ASA, ABS and PC, all the way to demanding materials such as polyamides (nylon). In this way, CORE One covers virtually every area: from easy and seamless printing at home to the production of rapid prototypes, durable functional parts and even finished products ready to ship to customers.

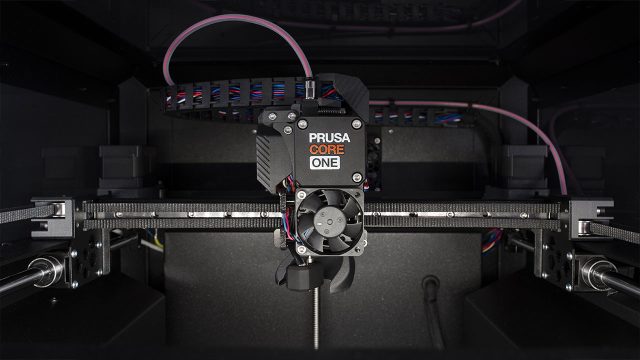

CoreXY – Prusa Style

We have always designed our machines as 3D printing workhorses because we rely on them in our production. We run a 3D printing farm with over 600 printers and CORE One’s compact design will allow us to fit even more machines in the same space. And we’ve done more things to make CORE One best print farm machine: compact size is one thing, but there’s more. Thanks to the fans at the back, you can connect the printer to the air extraction system, the door opens 180° so they don’t stick out and block a narrower space/corridor. You can even flip the hinges and door to the other side. And the whole machine is made with thought for low maintenance and long life.

I always say that there will never be a part in our machines that is just for design. Everything has a purpose. Most of the materials used are easily recyclable indefinitely and will last a lifetime. For the frame we use laser cut steel profiles, which is a really efficient but also incredibly precise manufacturing method (with tolerances <of 0.1mm). The same goes for the CoreXY portal, which is a rectangle made from a single piece of solid steel – this makes it incredibly robust and always perpendicular. So it’s impossible to get the XY axles wrong (trust me – we’ve tried).

The plastic parts are made of tough polycarbonate filled with carbon fiber. Nothing is welded, everything is connected with simple screws, so you can literally disassemble the entire printer with a simple screwdriver. We certainly didn’t want to reduce repairability: in fact, we improved it impressively – for example, the CoreXY function module can be replaced in less than 20 minutes. And if a guide mechanism wears out after thousands and thousands of hours of printing? Just remove a few screws and replace it – also because we’ve had spare parts available for years. There’s another great advantage to the design, it’s easily scalable – allowing us to be incredibly flexible in future projects. It’s designed to be a perpetual workhorse, easy to operate, easy to upgrade, productive and really the next chapter in our industrial design.

However, Core ONE is a true plug-and-print machine. Just unpack it, plug it in, run a quick one-time calibration and you’re done – in less than 10 minutes. If you have one of our printers, you’ll feel right at home. And if you’re completely new to 3D printing, you’ll find the CORE One an incredibly easy first step into this world. It’s a “start and forget” type of machine, where you just start the print and the rest happens completely automatically, without any user intervention. Plus, as always, we offer a host of courses , tutorials, guides and more from Prusa Academy .

Do it your way!

Because we use real metal almost everywhere, you can easily design all kinds of holders, organizers and shelves and attach them using magnets on the side of the printer – the empty recess on the left side is the ideal place for such projects. This also opens up a huge field for all sorts of personalization, modification and customization. I can already imagine these printers masquerading as Claptrap from Borderlands or maybe dressed up with themes from Star Wars… I’m almost sure we’ll see some really creative ideas!

There’s no problem modifying printed components, attaching new parts using magnets or screws, and generally experimenting with CORE One as much as you like. Of course, our software and firmware are open source, which gives you even more opportunities to experiment. And this is where we thought there was room for improvement.

In the past, in order to flash custom firmware on all of our printers equipped with the Buddy board, you had to break a special seal and that meant voiding the warranty. Not anymore: we are making a huge positive change in order to make the printer even more community-friendly and motivate developers to dig into the code and come up with all sorts of settings and customizations. From now on, breaking the seal will not void your warranty, so you can freely flash custom firmware. However, since there is no way to verify or test every single custom firmware on the internet, we disclaim any responsibility for any damage or harm that a broken printer may cause. This applies to the MK4/S, XL, MINI and also the new CORE One. So please do not flash suspicious files senselessly.

Expand it with add-ons!

GPIO hacker board and the accelerometer are fully compatible from the start. The GPIO module is an excellent tool for modders, hackers and 3D printer hobbyists who love to add new features to their 3D printers. It connects to the I2C port on the xBuddy board, allowing you to control and receive input from external devices. You can create a trigger for your camera and a slider to capture precise timelapse photos, control external LED lighting, control servomotors and much more – you name it! You can set all commands directly in PrusaSlicer.

The accelerometer is not necessary for our factory setup machines, but will be useful for all developers and modders of printers. With it you can easily measure the resonant frequency of the custom print head and recalibrate your Input Shaper to optimal values.

And more accessories to come: we are finishing the development of two types of filtration (HEPA filter and advanced filtration system) and a dry box. We will send out a newsletter as soon as these accessories become available.

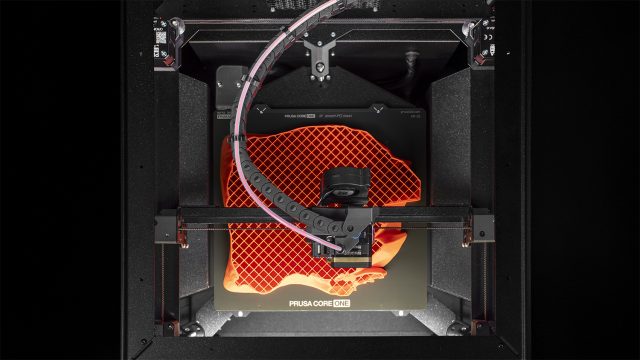

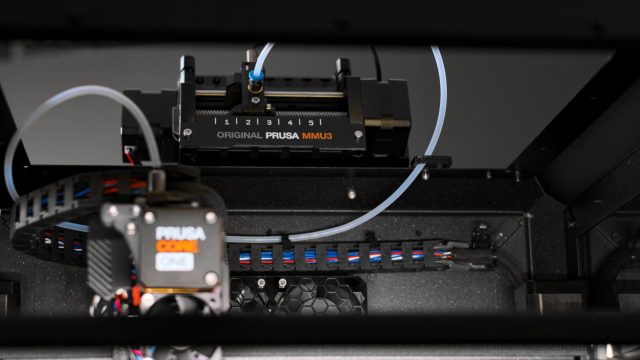

Plus, you can count on full support for the most effective single-nozzle multi-color solution, MMU3. The device is fully compatible with the Prusa CORE One and will allow you to print beautiful, colorful objects with up to five filaments simultaneously. Unlike other multi-filament printers that can generate a surprising amount of waste (sometimes almost equal to the weight of the printed object), our printer uses an innovative compact cleaning tower to manage filament changes. This not only reduces filament waste, but also minimizes waste to a single, tidy block.

Introducing the Buddy3D camera

With Prusa CORE One we also present a new optional camera Buddy3D will cover all types of 3D printer accessories, manufactured by external suppliers but entirely under our supervision and control. The same goes for the camera. It will come as a small module that will be placed inside the CORE One camera and connected via USB-C cable to the motherboard. The firmware for the camera was created under our close supervision, so we can guarantee 100% security.

The camera is scheduled to be ready in the same timeframe as the Prusa CORE One, so stay tuned – we’ll give you the opportunity to edit your order and add the camera in case you order the printer before the camera becomes available. Same camera, albeit in a different housing, will also be available for MK4S and XL. Please note that the camera requires an active Wi-Fi connection and is fully integrated with the Prusa Connect and Prusa App.

Seamless workflow, 100% security

Years ago, when we released the original Prusa MK2, it was a pretty big deal to distribute a customized slicer and factory tested print profiles with it. Then we added Prusament . И Prusa Connect . И Printables , Prusa App, Academy …

Now, with Prusa CORE One, you’ll get a ticket for the whole “Prusaverse” :-). Everything you need is under one roof. You can download hundreds of thousands of free 3D models from Printables.com – in fact, you can send them directly to PrusaSlicer with one click, cut them up and send them over the web for instant printing. You can take advantage of our remote print management system, Prusa Connect, or from the built-in Prusa app for iOS/Android if you want to monitor your prints remotely – but this is completely optional. If you prefer, you can still use a standard USB drive to transfer files.

All of the high-quality filaments we produce ourselves have their own profiles in PrusaSlicer, but we also prepare profiles for multiple third-party filaments (over 200 in total), so you’ll always get the best performance no matter which material you choose. You don’t have to be a professional to get professional-level results.

And we always put security first. We’ll never force you to connect your printer to the network – not for initial configuration, not for firmware updates, not for slicing. Never. And you’ll still get a complete experience. You can even turn off the Wi-Fi module for the highest security jobs. It’s entirely up to you whether you want to connect a USB-C camera for print monitoring, add your printer to Prusa Connect, or monitor your prints with the Prusa app. Our code is open source, so you can always do an independent audit and check that we’re not cheating or stealing your files, even when you’re not connected to the internet. You can sleep easy knowing that the product you’re working on won’t suddenly appear on Temu.

One more thing…

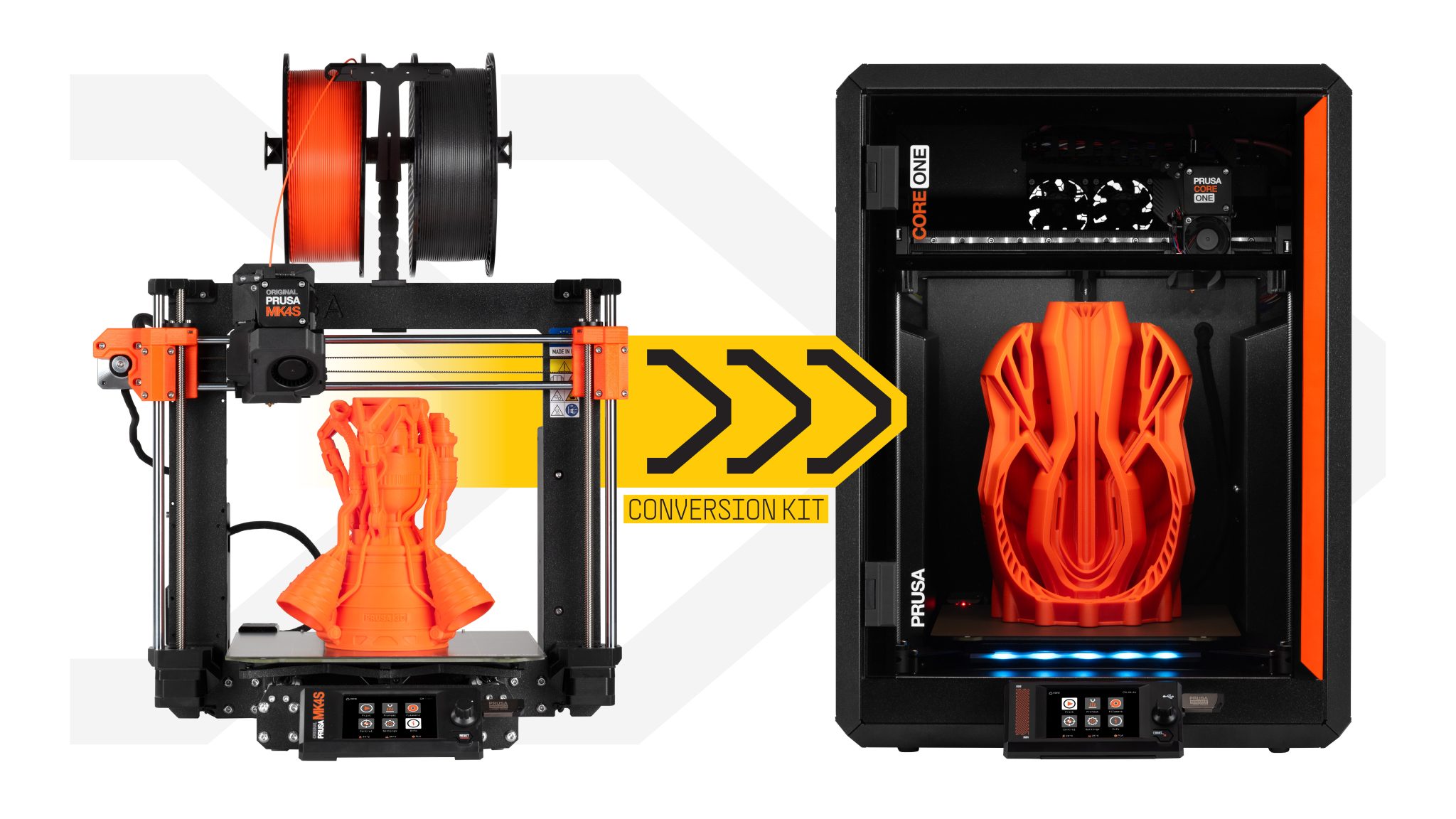

One thing I haven’t mentioned yet: upgrade kits. With our machines there has always been an upgrade path, you can always upgrade your existing model to the latest version. Now when you look at the new Prusa CORE One, you can see that it’s a very different machine compared to the MK4S. Fully enclosed with CoreXY kinematics, much higher print volume, etc. And yet, we have made it possible to convert your current MK4S to CORE One using a conversion kit. So you’re actually converting one product line into another.

The kit for Prusa CORE One conversion is cheaper than the MK3S->MK4 upgrade kit and will allow you to transform your MK4S completely into a CORE One without any compromise.

The conversion can only be done with the MK4S parts, not the MK4, because all the components from the MK4S upgrade kit are also used for the conversion.

It also means that CORE One offers outstanding backward compatibility. You probably know what it’s like when a new gadget comes out, like a phone – it’s cool, but also a bit inconvenient because you have to buy a new case, maybe the charging port is different so you need a new cable, etc. The CORE One uses the same printed sheets as the MK3/MK4, and also hotends, nozzles and other proven parts from the MK4S. This is extremely handy if you use, for example, dozens of our printers in your print farm as it significantly reduces the initial cost! We know that many of our customers have purchased additional printing sheets and nozzles and we wanted to make sure they all still fit.

And yes, although the printer may look like a solid monolith, there will also be Prusa CORE One assembly kit! Assembling your own printer is still a hugely popular choice because it gives you a full insight into how a 3D printer works. And it’s not just for hobbyists. Many companies buy assembly kits along with the assembled printers so employees can learn all the ins and outs. And the CORE One is even easier to assemble than the MK4S.

So this is CORE One. A fully enclosed, high-speed CoreXY 3D printer focused on quality and designed to print PLA and PETG with a closed door. We’ve spent a lot of time making the design resistant to change and modular so we can use it as the basis for upgrades for years to come, like my design with the i3.

Nice print!

Joe Prusa

@3dbgprint